Brazed-plate exchangers (BPHEs) are highly efficient heat transfer devices used throughout various industries owing to their small size and high capabilities. This article will explore the characteristics of, advantages, and applications of brazed plate heat exchanger, as well as the methods of together screws vacuum pumps could boost the efficiency of BPHEs.

What is a Brazed Plate Heat Exchanger?

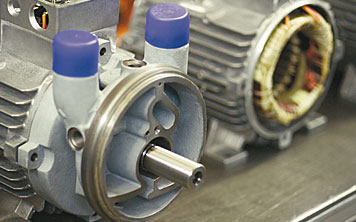

Brazed-plate heat exchanger could be defined as a type of heat exchanger composed of numerous tiny, flat plates that stack. The plates are a collection of channels that allow for fluids can flow, and let heat flow rapidly from one place to the next. They are then brazed with high temperatures making a very sturdy and small piece of equipment with the need for seals and gaskets.

Components and Design

Plates

The brazed heat exchangers typically are made of stainless steel. This metal has exceptional thermal conductivity, as well as resists corrosion. Each plate is constructed with specific patterns which produce a turbulent flow that enhances the flow of heat.

Brazing Material

They are joined using a filler substance, usually copper or nickel. Brazing creates an extremely solid connection between the plates that guarantees that the exchanger can endure extreme temperatures and pressures.

Inlet and Outlet Connections

Connections to inlet and outlet outlets for all fluids. This allows easy integration in different systems. Connections are typically threaded or made of flanges, depending on the requirements specific to every system.

Advantages of Brazed Plate Heat Exchangers

Compact Size

The main advantage of brazed plate heat exchangers is the small dimension. This design permits the use of large surfaces with less footprint, which allows BPHEs great for locations where space is restricted.

High Efficiency

Corrugated plates produce turbulent flow within the fluid and boost the efficiency in the energy transfer. This payoff results in high-efficiency heat exchange allowing BPHEs ideal for areas where high performance needs to be achieved.

Durability

Brazed construction of BPHEs eliminates the requirement for gaskets or seals and also reduces the risk of leaks as well as the need for maintenance. The powerful bonds created by brazing assure the durability and endurance of.

Versatility

BPHEs can operate with a wide number of temperatures and pressures making them ideal to be used in a range of different ways. They also utilize various fluids including refrigerants chemical, oils, and much more.

Applications of Brazed Plate Heat Exchangers

HVAC Systems

Heating, ventilating, and cooling (HVAC) systems, and heat exchangers constructed of brazed plates can be used for cooling and heating functions. Their size is tiny and their effective efficiency makes them ideal for heat pumps, chillers as well as air conditioning units.

Refrigeration

They are commonly utilized in systems of refrigeration that include condensers as well as evaporates. The ability of BPHEs to withstand extreme temperatures and pressures makes them suitable for the most recent technology in refrigeration.

Industrial Processes

In many industrial processes, including chemical processing, extraction of oil and gas, and power generation, brazed plate heat exchangers are used for cooling and heating liquids. Their endurance and efficiency are perfect to be used in the toughest industrial processes.

Renewable Energy Systems

BPHEs are also employed in renewable energy sources like geothermal and solar thermal technology. Their efficiency is very high, which assists in to rise in efficiency in energy transfer makes them more efficient and eco-friendly.

The Role of Screw Vacuum Pumps in Enhancing BPHE Efficiency

The function of screw vacuum pumps plays a major factor in increasing the efficiency of brazed plates to facilitate heating exchange. Through the creation of a vacuum, they reduce the temperature of the liquid and increase the effectiveness of heat exchange. Below are how screw vacuum pumps can be integrated with the BPHE system:

Evaporation Processes

About evaporated liquids, screw vacuum pumps can reduce the boiling point of the liquid. This allows for lower pressures and operating temperatures. This is not only beneficial in terms of heating transfer and cooling, but it can also decrease the use of energy and operating expenses.

Condensation Processes

The process of condensation uses pumping with screws, these serve the vacuum needed to promote efficient condensation in low temperatures. This outcome results in better performance of the heating exchanger and less pressure on the components of the system.

Degassing

Screw vacuum pumps can be utilized to extract gases from liquids before being absorbed into the heat exchanger composed of brazed plates. Removal of gas from the liquids helps in stopping cavitation and will also guarantee a smooth performance. This increases the efficiency the heat exchanger can obtain.

Conclusion

The Brazed Plate heat exchangers can be described as a highly efficient and adaptable device that serves a crucial role in a variety of industrial processes. Their size and small size, along with their high effectiveness and endurance make them the ideal choice for HVAC systems, industrial processes, refrigeration, and solar energy sources. Incorporating screw vacuum pumps in BPHE systems can further boost their effectiveness by increasing the effectiveness of their transfer of heat while decreasing the energy consumption. Knowing the advantages and benefits of brazed plate heat exchangers will help companies select the right type of heat exchanger that is suited to their needs, and assure top quality and efficiency as well as the most cost-effective.